Are you trying to decide between HDPC and SPC for your next project or product? Understanding the key differences can save you time, money, and frustration.

You might be wondering which option fits your needs best, or how each one impacts quality and performance. This article will break down everything you need to know in a clear, simple way—so you can make the smartest choice with confidence.

Keep reading, and by the end, you’ll have a clear picture of HDPC vs SPC and how it matters to you.

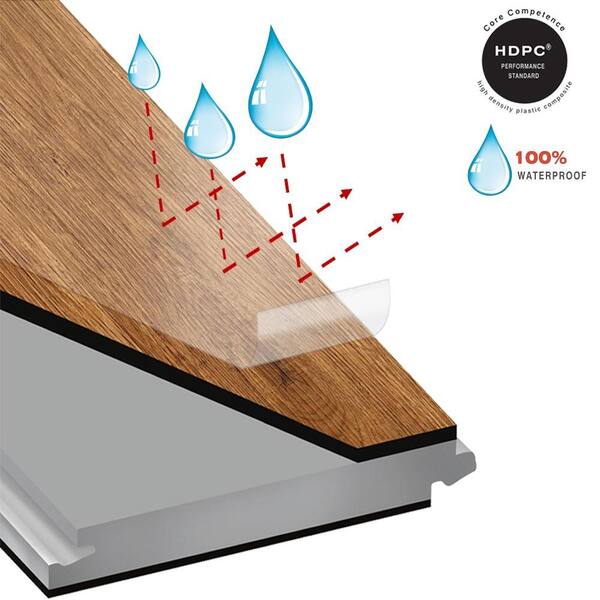

Credit: www.homedepot.com

Material Composition

Material composition plays a key role in defining the quality and durability of HDPC and SPC flooring. Both types use different materials that affect their strength, water resistance, and installation ease. Understanding these differences helps in choosing the right flooring for your needs.

Core Structure Differences

HDPC floors have a high-density polymer core. This core is rigid and provides strong support. It helps HDPC resist dents and impacts.

SPC floors use a stone-plastic composite core. This core mixes limestone powder with plastic. It makes SPC very dense and hard.

The SPC core is heavier and more stable than HDPC. It handles moisture better and stays flat over time.

Surface Layer Variations

HDPC surfaces have a thick, protective wear layer. This layer guards against scratches and stains. It also gives a smooth finish.

SPC surfaces use a similar wear layer but often add an extra vinyl layer. This extra layer boosts water resistance and durability.

Both surfaces offer good texture and grip. Yet, SPC’s surface is usually harder and more resistant to damage.

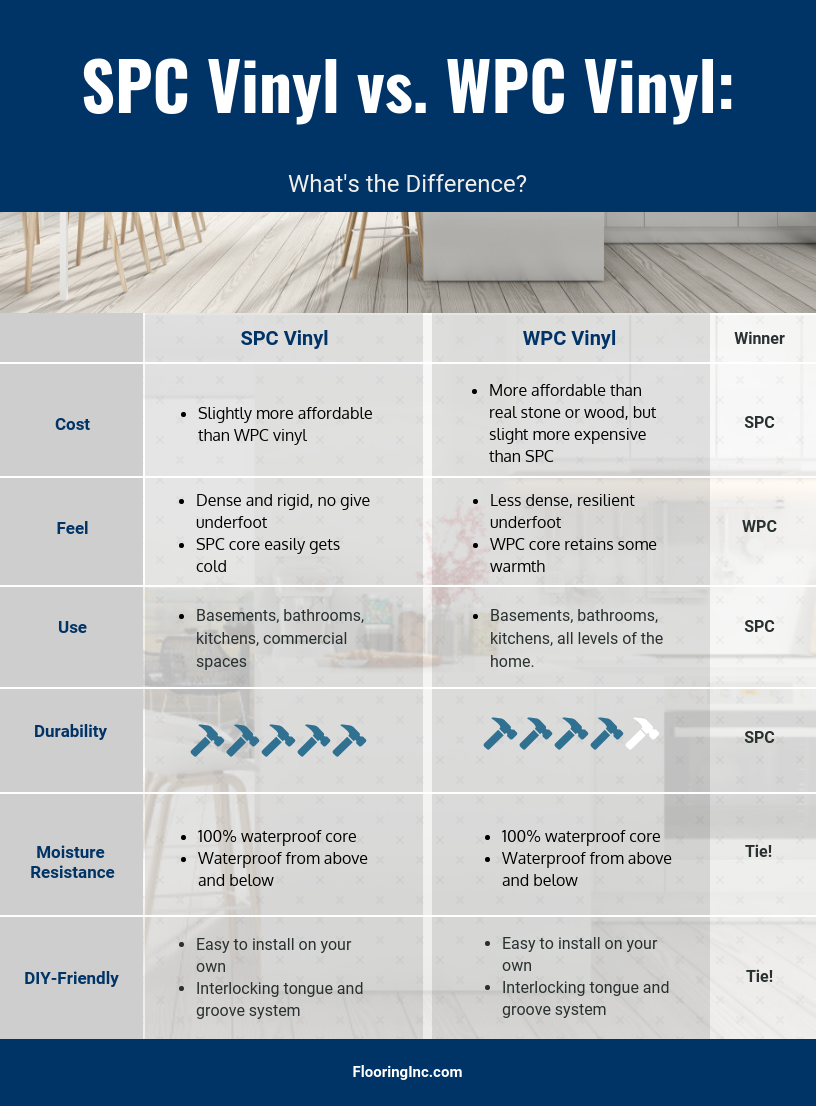

Credit: www.flooringinc.com

Durability Factors

Durability is a key factor when choosing between HDPC and SPC flooring. These materials face daily wear and tear. Understanding their durability helps pick the best option for your needs.

Scratch And Impact Resistance

HDPC offers good resistance to scratches but can dent from heavy impact. It has a softer surface layer compared to SPC. SPC is denser and harder, making it more resistant to scratches and dents. It handles heavy foot traffic better. SPC is ideal for homes with pets or kids who may cause damage.

Waterproof Capabilities

SPC flooring is fully waterproof due to its stone-plastic core. It does not swell or warp when exposed to water. HDPC has a wood-plastic core that is water-resistant but not fully waterproof. It may swell if water sits on the surface for a long time. SPC works well in moisture-prone areas like kitchens and bathrooms. HDPC fits best in drier spaces.

Installation Methods

Choosing the right installation method is key for HDPC and SPC flooring. Each method affects the ease, time, and tools needed for installation. Understanding these options helps make a smart choice for your space.

Click-lock Systems

Click-lock systems are popular for both HDPC and SPC floors. They let you snap planks together without glue. This method is fast and clean. No mess, no drying time. Perfect for DIY projects.

The planks fit tightly, creating a stable floor. You can even install over existing floors in many cases. Click-lock floors are easy to remove or replace too. Ideal for renters or those who like change.

Glue-down Options

Glue-down installation uses adhesive to fix planks to the subfloor. It offers strong, permanent bonding. This method works well on uneven surfaces.

Glue-down is common for HDPC floors due to their flexibility. It reduces noise and adds durability. The process takes more time and requires careful preparation.

SPC floors can also use glue-down, especially in commercial spaces. This method helps the floor stay in place under heavy traffic. It’s less popular for DIY because of the mess and drying time.

Aesthetic Appeal

Aesthetic appeal plays a big role in choosing between HDPC and SPC flooring. It affects the look and feel of any room. Both types offer unique styles to enhance home interiors. Understanding their design and color options helps make a clear choice.

Design And Texture Options

HDPC floors offer a natural wood look with detailed grains. The texture feels warm and soft underfoot. This type mimics real hardwood closely. SPC floors have a smoother surface and can copy wood, stone, or tile patterns. They look modern and clean. Textures vary from matte to glossy finishes, fitting many styles.

Color And Finish Range

HDPC comes in warm wood tones like oak, walnut, and cherry. These shades create cozy, inviting spaces. SPC offers a wider color range, including gray, beige, and even bold colors. Its finishes can be matte, satin, or shiny. This variety suits both classic and contemporary rooms.

Maintenance Needs

Maintenance needs differ between HDPC and SPC flooring. Understanding these needs helps keep floors looking good and lasting longer. Both materials require care but in different ways. Knowing the right methods avoids damage and costly repairs.

Cleaning Techniques

HDPC floors need gentle cleaning. Use a soft broom or vacuum to remove dirt. Avoid wet mops with too much water. A damp mop with mild soap works best. Do not use harsh chemicals or abrasive tools.

SPC floors are more water-resistant. You can use a wet mop but avoid soaking the floor. Use gentle cleaners made for vinyl or stone plastic composite. Avoid wax or polish, as they can make floors slippery.

Long-term Care Tips

Protect HDPC floors from heavy furniture by using pads under legs. Avoid dragging furniture across the floor. Regularly check for scratches or dents and repair them quickly. Keep the room humidity stable to prevent warping.

SPC floors need less humidity control but still avoid extreme moisture. Place mats at entrances to reduce dirt and grit. Clean spills immediately to prevent stains. Maintain a steady indoor temperature for best results.

Cost Comparison

Comparing the costs of HDPC and SPC flooring helps you decide which fits your budget. Both types have different price points and long-term expenses. Understanding these can save money and avoid surprises later. Below is a breakdown of initial costs and value over time.

Initial Investment

HDPC flooring usually costs less upfront than SPC. The price depends on thickness and design. Installation costs for HDPC can be higher due to its need for a flat subfloor. SPC tends to be pricier but often includes easier installation. This can lower labor costs and time.

Value Over Time

SPC flooring is more durable and resists dents and water better. It lasts longer, reducing replacement frequency. HDPC may need repairs or replacement sooner. Over years, SPC can be more cost-effective despite higher initial price. Consider maintenance costs and durability for true value.

Environmental Impact

Understanding the environmental impact of HDPC and SPC flooring helps make better choices. Both materials affect nature differently during production and disposal. Exploring their sustainability and recyclability reveals which option is greener.

Choosing flooring that harms the planet less supports a cleaner future. Each type has pros and cons regarding resources used and waste created. Knowing these details guides eco-friendly decisions for your home or project.

Sustainability Factors

HDPC flooring often uses natural wood fibers mixed with resins. This mix can lower the need for pure plastic, saving fossil fuels. The production process for HDPC uses less energy than SPC. SPC flooring contains more plastic and limestone, which involves more mining and processing. HDPC may degrade faster in nature, but SPC lasts longer indoors. Both types avoid harmful chemicals found in traditional vinyl flooring. Choosing products with eco-certifications ensures better sustainability practices.

Recyclability

Recycling HDPC flooring is easier due to its wood content. It can sometimes be processed with other wood waste. SPC flooring is mainly plastic, making recycling harder and less common. Some facilities accept SPC, but many do not. Improper disposal of SPC can add to plastic pollution. HDPC’s wood fibers break down naturally if discarded correctly. Both floors benefit from reuse or repurposing to reduce landfill waste. Checking local recycling options helps manage end-of-life flooring responsibly.

Credit: www.homedepot.com

Best Use Cases

Choosing between HDPC and SPC flooring depends on where you plan to use it. Each type fits better in certain places. Understanding the best use cases helps you pick the right flooring for your needs.

Residential Settings

HDPC flooring works well in homes. It handles everyday wear and tear nicely. Ideal for living rooms, bedrooms, and hallways. It offers good comfort underfoot. SPC flooring suits kitchens and bathrooms. It resists moisture and spills better. SPC is also great for basements. Both options bring style and function to homes.

Commercial Applications

SPC flooring is popular in busy commercial spaces. It stands up to heavy foot traffic. Offices, retail stores, and restaurants benefit from its durability. HDPC can fit light commercial use too. Places with less traffic, like small offices, may use it. SPC’s water resistance helps in commercial kitchens. Both types provide long-lasting floors for business needs.

Frequently Asked Questions

What Is The Main Difference Between Hdpc And Spc Flooring?

HDPC flooring is thicker and more durable than SPC. SPC is thinner but offers better waterproof resistance.

Which Flooring Is Better For Moisture Resistance, Hdpc Or Spc?

SPC flooring provides superior moisture resistance. HDPC is water-resistant but not fully waterproof.

Is Hdpc Flooring Easier To Install Compared To Spc?

Both HDPC and SPC have click-lock systems. SPC is slightly easier due to its lighter weight.

Which Flooring Option Is More Cost-effective, Hdpc Or Spc?

SPC flooring usually costs less than HDPC. HDPC offers better durability but at a higher price.

Conclusion

Choosing between HDPC and SPC depends on your needs and budget. HDPC offers a smooth, natural look. SPC is more durable and water-resistant. Both types have pros and cons to consider. Think about where you will use the flooring. Also, consider how much maintenance you want.

This will help you pick the right option. Take your time to decide. Your choice affects comfort and style for years.